Filters

The Bernoulli’s Cleaning Technology

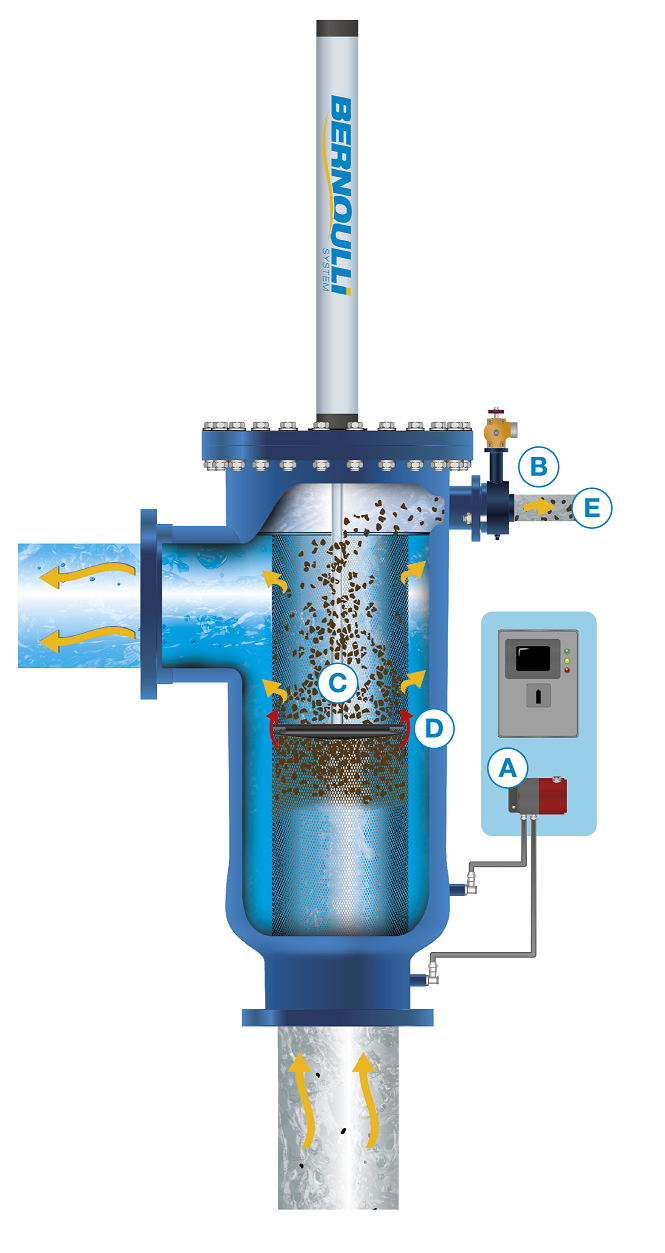

Bernoulli System pioneered the application of the Bernoulli Principle, named after the Swiss scientist Daniel Bernoulli, to water filtration. The distinguishing feature of a Bernoulli Filter is a disc mounted on a pneumatic cylinder, which enables contactless cleaning of the filter. The cleaning sequence itself is automatic and continuous, requiring no manual intervention.

A.The flushing sequence is initiated by a timer setting or triggered by a differential pressure sensor before any blockage of the filter basket causes flow reduction.

B.In the pre-flushing stage, the flushing valve opens and larger particles are flushed out.

C.During the flushing sequence, a specially shaped flushing disc mounted on a pneumatic cylinder enters the filter basket and creates a gap between the disc and the filter basket.

D.As the flow velocity increases locally around the disc, the static pressure is reduced in accordance with the Bernoulli Principle and the direction of the flow is reversed, thus releasing particles which are stuck to the surface of the filter basket.

E.The released particles are led out from the filter through the flushing outlet.

Bernoulli Manual Filter

|

Our manual filters are designed to be operated either as by-pass filters (together with an automatic filter) or as guard/police filters in closed systems or systems with low particle content. The MSG product line consists of six models, DN100 (4”) – DN350 (14”), handling capacities up to 1600 m3/h. Like its automatic sibling, the MSG filter is durable and light weight thanks to its design in GRP (glass fiber reinforced polyester). There are two types of filter baskets; perforated or wedge-wire. Our standard filter basket range is made in stainless steel (316L) or titanium but other metals like Duplex stainless steel and Super Duplex stainless steel can also be used if required.

|

Single basket bernoulli filter

|

The product line was introduced in order to meet the tough corrosion challenges faced by products operating with seawater. With its design in GRP (glass fiber reinforced polyester) the BSG filter benefits material durability and large weight savings. In the BSG product line, capacities of up to 6400 m3/h can be supported among the eleven models, DN 100(4”) –DN700 (28”), offering by us. There are two types of filter baskets; perforated or wedge-wire. Our standard filter basket range is made in stainless steel (316L) or titanium but other metals like Duplex stainless steel and Super Duplex stainless steel can also be used if required. |

Bernoulli multi- basket filter

|

The multi-basket Bernoulli Filter was developed to meet a market demand for finer filtration in combination with large capacities. It consists of four models, DN 400 (16”) to DN 800 (32”), covering a capacity range of up to 8400 m3/h. Thanks to the use of multiple filter baskets in one filter body, fine filtration down to 100 microns is achievable, even at high flow rates. This means that one single multi-basket unit is capable of doing the work of multiple smaller single basket units. The result is a space efficient installation that requires less piping. Like the single-basket BSG product line, the BMG product line benefits from the use of GRP (Glass fiber Reinforced Polyester) as filter body material, which is the superior material of choice for seawater applications. Since customisation is vital to our business, multi-basket Bernoulli Filters can be manufactured in several steel materials to comply with customer’s specific requirements and needs. |

centrifugal separator

|

A centrifugal separator is not actually a filter since there is no screen element inside to filter out the particles. The separation is instead ensured by means of centrifugal force, and the separator’s efficiency is directly proportional to the specific density and size distribution of the particles. The centrifugal separator eliminates 98% of all particles with a specific gravity of 2.6-2.8 (such as sand) down to a size of 75 microns, provided that the pressure loss over the unit is minimum 0.3 bar. Centrifugal separators should be installed downstream of the feed pump in order to ensure enough pressure during purging, and to overcome the pressure drop over the unit. The CXWL product line is the near twin of the CXWV product line. The only difference is that they have leaning support legs to support installations with height limitations. Available sizes are DN100-500, with capacities of up to 2700 m3/h. The CXWL product line comes in three different materials: carbon steel (CKWV), stainless steel AISI 304 (CRWV) and stainless steel AISI 316 (CSWV). Like the CXWV product line, the CXWL is available in dismountable models. |