Level Instruments

Level Guages

Jogler level products are custom designed to meet customer specifications and manufactured to applicable ASME B31.1 and B31.3 code requirements to ensure reliable operation and maintenance free design. Jogler’s manufacturing capabilities have increased to include CNC machining, advanced machine for extruded process connections, welding machines, water jet machine, glass lathe, in-house powder paint capabilities. Also offers X-ray, PMI with and without carbon content, post weld heat treatment, epoxy painting, clean service for oxygen.

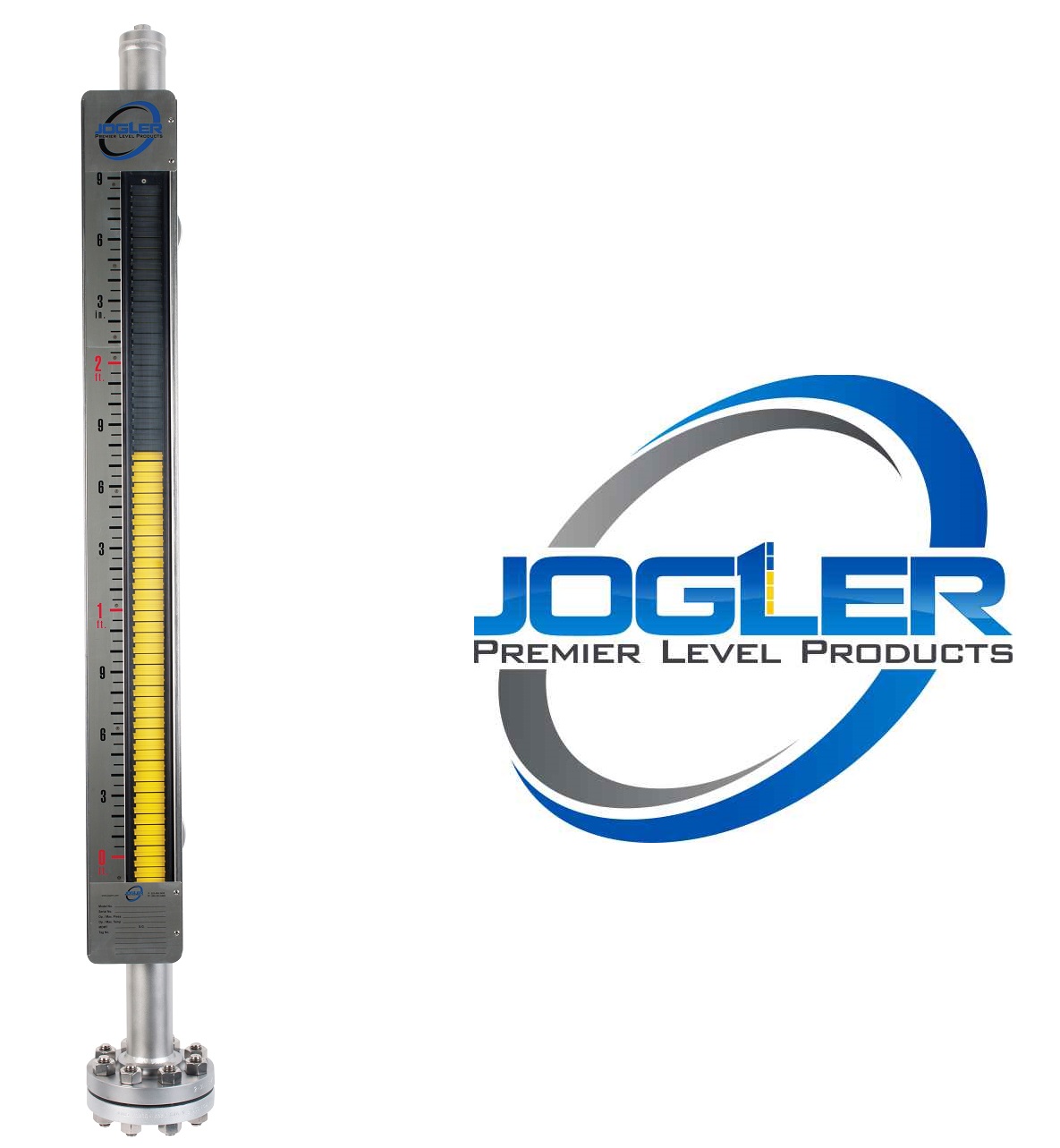

JMG MAGNETIC LEVEL GAUGE

|

JMG Magnetic Level Gauges are a safe, economical way to measure and control level through a wide range of process pressures, temperatures, and fluids. Each component of the JMG (chamber, float, and indicator) has been engineered to improve on existing designs to ensure reliable, maintenance-free operation right out of the crate. The JMG can be coupled with an MGT magnetostrictive level transmitter and/or any Jogler level switch to provide control outputs configured to specific customer needs.

|

JXC EXTERNAL CHAMBER

|

JXC External Chambers are custom configurable ASME compliant pressure vessels for use with many different types of instruments including ILT Magnetostrictive Level Transmitters, Guided Wave Radars, Capacitance probes, Tuning Fork switches, and others. The JXC is custom engineered to mate with new or existing customer piping and instruments to allow for hassle-free installations with minimal in-field fabrication.

|

Level Transmitters

Our level sensor product line provide high-reliability monitoring and detection of a wide range of fluid media. Area of application can range from the sensing of cooking oil, to hydraulic fluids, to diesel fuel tanks (gas level indicator), to water and wastewater, to biohazards, to even deionized or potable water.

To effectively address such a wide variety of measurement challenges, we offer a broad range of contact, non-contact, and non-intrusive liquid level sensors. Multiple liquid level sensing technologies may also be incorporated within a single application.

VEGAPULS 64 Non contact level transmitter

|

The VEGAPULS 64 is a sensor for continuous level measurement of liquids. With small tanks or in case of narrow space the small process fittings offer special advantages. The very good signal focusing enables the use in vessels with many installations such as e.g. stirrers and heating spirals. Technical Specification Measuring range – Distance 30 m Process temperature -196 … 200 °C Process pressure -1 … 25 bar Accuracy ± 1 mm Version

Output 4 … 20 mA/HART – two-wire Ambient temperature -40 … 80 °C Get a Quote

|

VEGAFLEX 81 GUIDED WAVE RADAR SENSOR

|

The VEGAFLEX 81 guided radar sensor is exceptional when it comes to measuring the level or interface of liquids. Guided radar is extremely versatile and can be found in almost every industrial sector. Whether bitumen or liquefied gas, in storage containers or standpipes, in a metering tank or in tank farms – VEGAFLEX 81 measures the level or interface (separation layers) of liquids with great reliability and accuracy. Guided radar delivers reliable measurements data for control or safety systems for

Technical Specification

|

MGT-6000 MAGNETOSTRICTIVE LEVEL TRANSMITTER

|

The MGT-6000 Magnetostrictive Level Transmitter is a loop powered non-contact level measurement device that is mounted externally to a magnetic level gauge. Utilizing the magnetostrictive principle and time-of-flight calculations allow the MGT-6000 to provide a fast and accurate measurement of float position and, ultimately, liquid level in the gauge. Vibration-isolating elastomeric bushings ensure continuous operation in high vibration services.

|

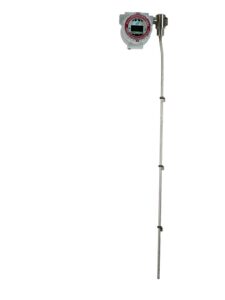

ILT-6000 DIRECT INSERTION MAGNETOSTRICTIVE LEVEL TRANSMITTER

|

The ILT-6000 Direct Insertion Magnetostrictive Level Transmitter is a loop powered non-contact level measurement device that can be installed directly into a process vessel. Utilizing the magnetostrictive principle and time-of-flight calculations allow the ILT-6000 to provide a fast and accurate measurement of float position and, ultimately, liquid level in the gauge. The ILT-6000 is installed in an isolation well assembly allowing the transmitter to be removed, serviced, or replaced with no process interruption.

|

Level Switches

Vega level switches are precise and reliable function due to product-independent switching point.they com with low maintenance costs and minimum time and cost expenditure .

VEGAVIB 61Vibrating level switch for granular bulk solids

|

The VEGAVIB 61 is a level switch for granular and coarse-grained bulk solids. The VEGAVIB 61 detects reliably and accurately the min. or max. limit level. The smooth surface of the vibrating rod, without corners and edges, avoids jamming of the bulk solid and is easy to clean. Technical Specification Measuring range – Distance –

Process temperature -50 … 250 °C

Process pressure -1 … 16 bar

Version

Standard

Detection of solids in water

Materials, wetted parts 316L

Threaded connection ≥ G1, ≥ 1 NPT

Flange connection ≥ DN 32, ≥ 1½”

Output

|

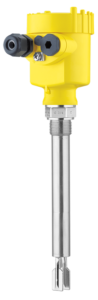

VEGASWING 63Vibrating level switch with tube extension for liquids

|

VEGASWING 63 is used as a universal level switch in all liquids. Independent of the mounting position it detects reliably with millimetre accuracy the level. The instrument can be used in vessels as empty or full detector, as approved overfill protection, dry run protection or pump protection. The position of the switching point is determined through the tube extension. The VEGASWING 63 offers high reliability and security in a wide application range. Technical Specification Process temperature -50 … 250 °C

Process pressure

-1 … 64 bar

Version

Standard

Hygienic applications

with gas-tight leadthrough

with tube extension

with temperature adapter

Output

Relay (DPDT)

Contactless electronic switch

Transistor (NPN/PNP)

Two-wire

NAMUR

Ambient temperature

-40 … 70 °C

|